-

13412197961

- 中文

13412197961

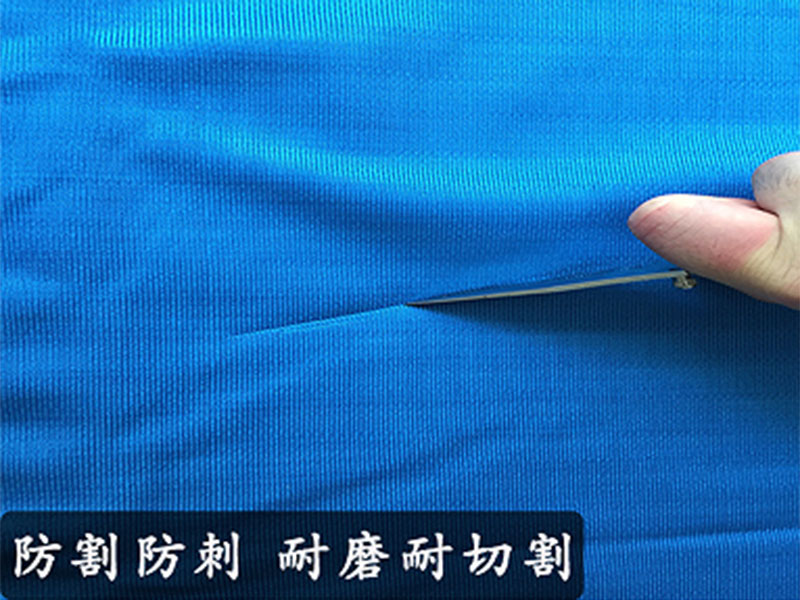

| Product Name | Anti cutting cloth |

| Material | UHMWPE/Polyester/Fiberglass |

| Wide width | 1.2/1.6 meters |

| Execution standards | EN388:2016 |

| Product specifications | 300/260 GSM ± 3%, etc |

| Anti cutting level | Level 2, Level 3, Level 4, Level 5 |

Raw material UHMWPE fiber: high molecular weight, high orientation, and high crystallinity. Its strength is 15 times that of steel and 10 times that of ordinary chemical fibers. In addition, it also has low density, high modulus, UV resistance, corrosion resistance, excellent impact and cutting resistance. It is one of the three high-strength fibers in carbon fiber and aramid fiber.

Application of UHMWPE fiber: Widely used in national defense equipment and special civilian fields, such as the production of tanks, armored vehicles, bulletproof plates, bulletproof helmets, bulletproof vests, anti cut jackets, anti cut gloves and fabrics, harbor ropes, naval vessels, and cables for deep-sea oil and gas drilling. Trawl nets, deep-sea anti wind and wave cages, sports equipment, and construction projects.

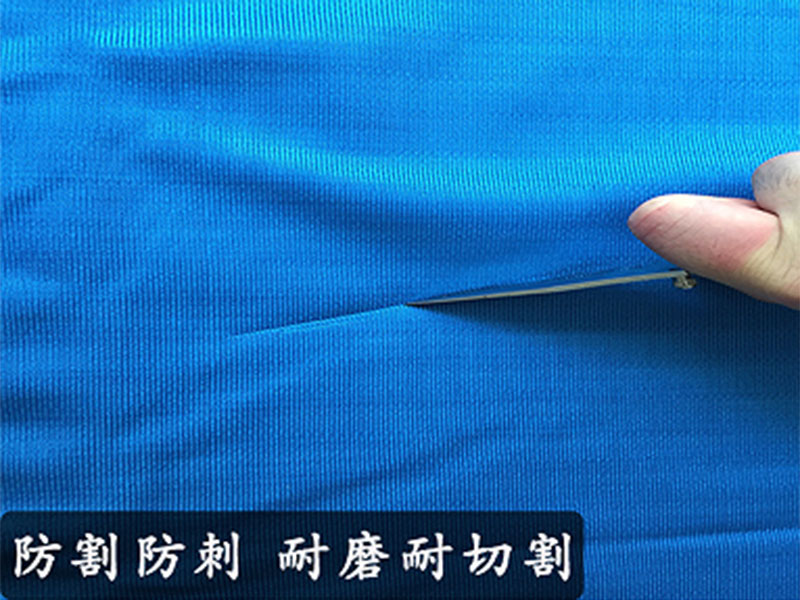

Cut resistant fabric is a type of ultra-high performance cut resistant fabric, which is innovatively combined with ultra-high molecular weight polyethylene (UHMWPE) and other technical fibers, and woven by a special high-density knitting machine.

It is made of high-strength and high modulus polyethylene (UHMWPE). It can be widely used in manufacturing, automotive industry and other fields, and can be made into cut resistant gloves, cut resistant clothing, bite resistant clothing, animal protective clothing and other products.

Excellent wear resistance, cutting resistance, and tear resistance

Specially made high-density textile knife resistant fabric, cool and comfortable to wear

Adopting PE5 grade anti cutting and anti fiber materials, innovative fabric design

Combining ultra-high molecular weight polyethylene with some special ultra-high molecular weight materials.

Suitable for metal manufacturing, sheet metal processing, tool production, glass, cutting and handling, precision grinding, slaughtering, kitchen operations.

Extremely low water absorption rate

Good insulation performance

Corrosion and chemical resistance

UV resistant

High strength and tear resistance

Low density, light weight (density less than water,<1 g/cm3)

Medium mechanical strength, rigidity, good creep resistance, and excellent machinability

High wear resistance: Wear resistant, low friction coefficient

Low temperature resistance

Link: